Look at the factories improving fastest right now. They aren’t adding more people; they’re eliminating more mistakes.

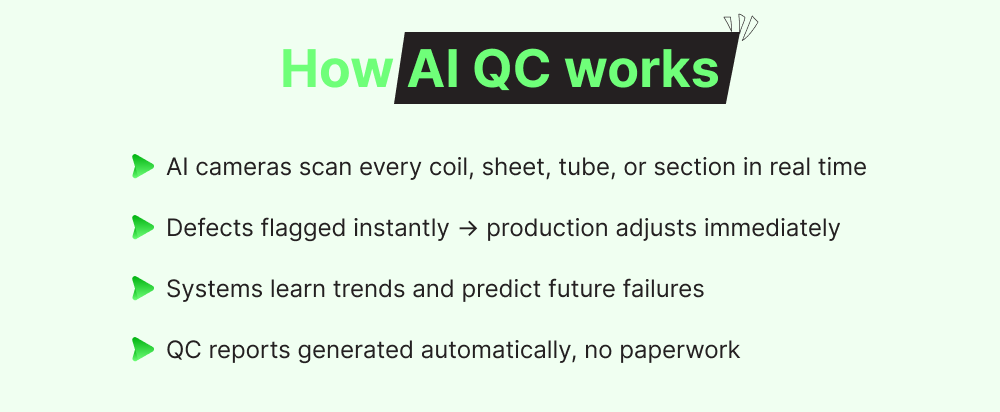

That’s the real shift happening in steel manufacturing: quality Control, moving from manual, reactive checks to automated systems that catch defects earlier, faster, and with near-perfect consistency.

Buyers want cleaner coils, tighter tolerances, and faster delivery. With manual Quality Control, even a single miss can cost you a customer or a year-long contract.

Latest data shows:

95% defect detection accuracy using AI vision systems

30-40% scrap reduction (equivalent to saving millions annually for mid-size plants)

Up to 50% faster quality control cycles, improving dispatch timelines

25-35% less rework, freeing 400-600 labour hours per month

In 2026, the manufacturing businesses with predictive QUALITY CONTROL will win more orders simply because they deliver cleaner material, consistently.

AI isn’t replacing your quality control team; it’s upgrading them.

Manufacturing businesses that automate even 10–20% of quality control workflows in 2025 will grow faster with the same workforce and fewer production interruptions.